On February 2, 2026, a lecture was held by Professor Tomás Poncí Dentinho of the University of the Azores (Portugal), who arrived at Kozybayev Univers Read more

Quotation gallery

Learning is finding out what you already know. Doing is demonstrating that you know it. Teaching is reminding others that they know it just as well as you. You are all learners, doers, teachers.

Faculty News

С радостью сообщаем, что наши коллеги Бакиров Алдияр и Ермеков Ерназ успешно прошли конкурсный отбор на прохождение научной стажировки по программе «5 Read more

От лица Центра агрокомпетенции Kozybayev University хотим поделиться важным шагом в профессиональном развитии нашей коллеги, доктора Сауле Мусуровой. Read more

On January 29, 2026, a meeting was held in the classroom No. 1 of the educational building No. 5, where 1st-year students of the Faculty of History, Read more

On January 30, 2026, students of the Faculty of History, Economics, and Law of Manash Kozybayev North Kazakhstan University took part in career guidan Read more

On January 29, 2026, a large-scale environmental fair "Darmarka" was held at the Manash Kozybayev North Kazakhstan University as part of the #StopMuso Read more

23 января 2026 года на факультете истории, экономики и права состоялась рабочая встреча представителей Управления государственных доходов г.Петропавло Read more

In mid-December 2025, the РА "Red Crescent Society of the Republic of Kazakhstan" held a short film competition on the theme "Fundamental Principles o Read more

On December 26, 2025, the Faculty of History, Economics and Law held a final meeting of the Faculty Council dedicated to summarizing the results of th Read more

17.12.2025 на медицинском факультете НАО СКУ им.М.Козыбаева началась экзаменационная сессия. С целью укрепление принципов академической честности, про Read more

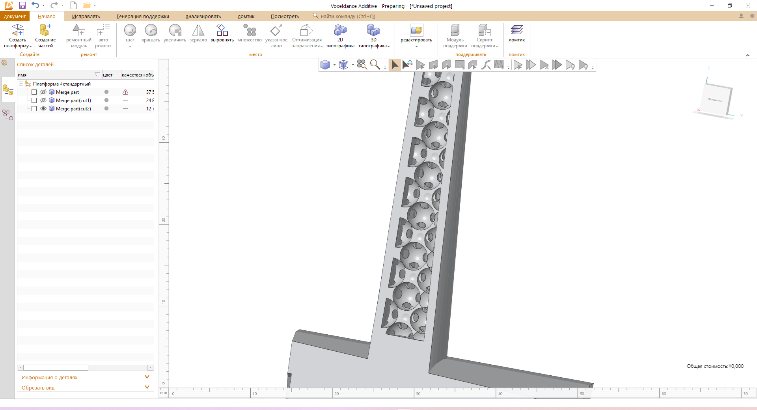

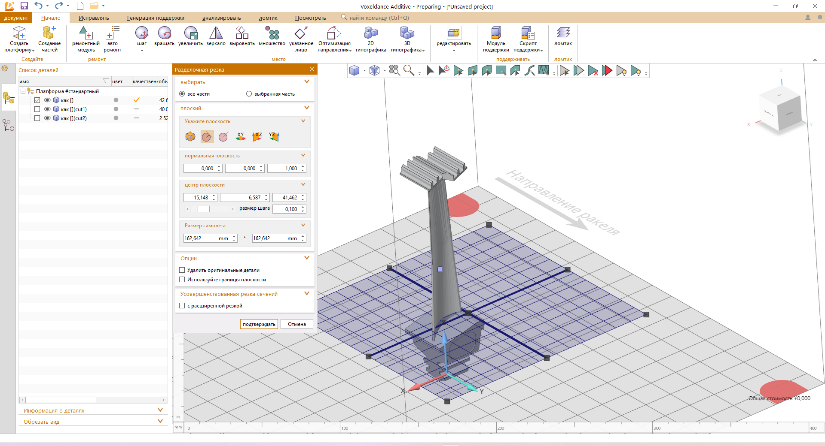

Разработка лазерной технологии изготовления комбинированных лопаток турбин ТЭЦ повышенной износостойкости, модифицированных диоксидом циркония концепции уровня Industry 4.0 на базе ISO/ASTM

The IRN AP26484701 project is being implemented as part of grant financing for 2024-2026. Ministry of Science and Higher Education of the Republic of Kazakhstan.

Project manager: Ratushnaya T.Yu., PhD (Hirsch Index h=5, https://orcid.org/0000-0002-8308-198X, Scopus Author ID: 57210393050, ResearcherID AAY-6445-2020)

Project executors: Ratushnaya T.Yu., Savinkin V.V., Kashevkin A.A., Dyachenko R.Yu., Lutsak S.M., Rakhmatulin M.L., Ivanishchev A.A.

Implementation period: 01.07.2024 – 31.12.2026

Total amount of financing: 119 876 373 tenge.

Project objective: Develop design and technological modules for honeycomb-shaped damper cells inside turbine blades that adapt structural and phase changes in the blades to turbine operating conditions.

Expected results: An integrated laser technology will be developed that will enable the production of adaptive thermal power plant (TPP) turbine blades with enhanced wear resistance, increasing microhardness by 12–18%; enhancing thermal stability to 950°C; reducing the friction coefficient to 0.18; and increasing the service life of TPP turbine blades by 28–32%.

Project Description: The use of technology for manufacturing innovative turbine blades with highly concentrated laser energy sources, the formation of a martensitic phase and systems of structural modules for stress redistribution will increase the energy efficiency and resource durability of turbine blades in the energy sector of Kazakhstan and increase competitiveness.

The implementation of the project will provide the development of a methodology for substantiating the optimal technological and economic characteristics of laser manufacturing of innovative turbine blades of energy complexes, ensuring the durability of high-load turbines with dynamic load, the methodology of synthesis, algorithmization, 3D prototyping, theory and practice of multifactorial experiment. It will make it possible to apply energy saving by introducing a module for adapting the phase changes of the blade to the operating modes of the turbine, redistributing power in the units, using the coercive resistance forces of the complex.